Hopson Chemical Industry

Hopson Chemical Industry

Hopson has over 16 years of experience in the development and manufacture of cyanoacrylates and is currently a leading manufacturer in this field.

We specialize in providing adhesive consulting services tailored for production applications, offering a wide range of customized products and packaging solutions.

We are well-equipped to specify and deliver the most cost-effective yet correct product for your production needs.

Hopson Adhesives is fully capable of supplying significant production quantities to large-scale multinational facilities.

Our manufacturing capacity exceeds 500 tons of Cyanoacrylate annually. For large-scale applications, products can be shipped directly to your production site, even via air freight if necessary.

At Hopson Adhesives, we are structured to provide unparalleled service and flexibility to meet all your requirements.

Yes, we can give you a free sample by freight collected. Click here to get the sample.

While Super Glue can be safely used to close superficial cuts, it is generally recommended not to use it for wound closure due to potential risks such as irritation and lack of flexibility.

Instead, for a safer and more effective option, consider using medical-grade adhesives like PerfectSeal medical skin glue. This skin glue for wounds is specifically designed for closing cuts and provides better adherence and healing properties.

Even though Cyanoacrylates are our specialty, Hopson Adhesives Manufacturer offers products in the following: epoxies, blu tacks, UV adhesives, glue sticks, silicones, glue dots, shoe adhesives, all-purpose glues, nail glues, eyelash glues, PVC cement, glue bottles, dispensing aids and equipment, solvents, cleaners, primers, activators, and removers.

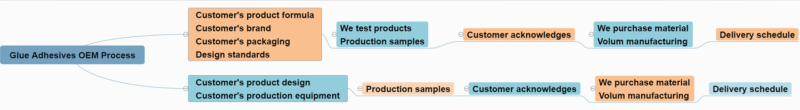

Warmly welcome for OEM order, we are confident of making first-class products for our valuable customers. Please send us your request

1. To ensure that the customer’s product technology and competitive advantage

Hopson is a leading high-tech enterprise with strong R&D capabilities and offers OEM services. Equipped with top-tier production facilities and technologies, we ensure our products meet customer specifications and technical requirements. High-quality products can satisfy customers and consumer confidence.

2. Shorten customer product time to market

Hopson has extensive resources and experience in large-scale production, which can rapidly carry out product research and development, and production-manufacturing, to save customer cost of research and development. Hopson commitment: customer benefit is of all, the shortest possible time to deliver goods, meeting customer’s competitive advantage demand.

3. To provide customers with complete solutions

At Hopson, our comprehensive solutions, powered by proprietary technology, facilitate OEM production of complementary products, offering customers a holistic solution and superior service.

We exemplify the principle of rational resource allocation, allowing OEM partners to more efficiently manage limited resources, reducing management costs, and enhancing operational effectiveness.

It depends on the order quantity. Normally, it takes about one month from the order confirmation

The adhesive is a fast-setting adhesive capable of adhering to most body tissue and many other materials, such as surgical gloves and stainless steel. Inadvertent contact with any body tissue, and any surfaces or equipment that are not disposable or that cannot be readily cleaned with a solvent such as acetone should be avoided.

Polymerization of the adhesive may be accelerated by water or fluids containing alcohol. The adhesive should not be applied to wet wounds.

The adhesive should not be applied to the eye. If contact with the eye occurs, flush the eye copiously with saline or water. If residual adhesive remains, apply topical ophthalmic ointment to help loosen the bond and contact an ophthalmologist.

When closing facial wounds near the eye with the adhesive, position the patient so that any runoff of adhesive is away from the eye. The eye should be closed and protected with gauze. Prophylactic placement of petroleum jelly around the eye, to act as a mechanical barrier or dam, can be effective in preventing inadvertent flow of adhesive into the eye. The adhesive will not adhere to skin pre-coated with petroleum jelly.

Therefore, avoid using petroleum jelly on any skin area where the adhesive is intended to adhere. Using the adhesive near the eye has inadvertently caused some patients’ eyelids to be sealed shut. In some of these cases, general anesthesia and surgical removal have been required to open the eyelid.

The adhesive should not be introduced into the wound since this would interfere with wound healing or cause foreign body reactions. Avoid excessive pressure of the applicator tip against wound edges or surrounding skin. This can force the wound edges apart and allow adhesive into the wound. The adhesive should be applied with a light brushing motion of the dropper tip over easily approximated wound edges.

The adhesive should not be used in areas of high skin tension or across areas in which tension may increase, such as knuckles, elbows, or knees, unless the joint will be immobilized during the skin healing period or unless skin tension has been removed by application of another wound closure device (e.g., sutures or skin staples) before application of the adhesive.

As with all wounds, the adhesive-treated wounds should be monitored for signs of infection. Wounds with signs of infection, such as erythema, edema, warmth, pain, and purulent exudate, should be evaluated and treated according to standard practice for infection. Patients should be instructed to contact the doctor if such signs as well as wound reopening or edge separation are found.

The adhesive should not be used on wound sites that will be subjected to repeated or prolonged moisture or friction.

The wounds should not be exposed to long periods of sunlight or tanning lamps during the healing period.

The adhesive should only be used after wounds have been thoroughly and adequately cleaned and debrided by standard surgical practice.

The adhesive polymerizes through an exothermic reaction in which a small amount of heat is released, and thus should not be applied to tissues that may be affected by such heat. The adhesive is to be applied in one continuous layer.

NOTE: Applying the adhesive in one continuous layer onto a dry wound will minimize the sensation of heat. Applying a second layer is not required or recommended.

If a second layer of the adhesive is applied or if large droplets of liquid are not spread thinly, the patient may experience an increased sensation of heat or discomfort.

NOTE: Excessive pressure of the dropper tip against the wound edges or surrounding skin can result in forcing the wound edges apart and allowing the adhesive into the wound.

The adhesive within the wound could delay wound healing and/or result in adverse cosmetic outcomes.

The adhesive is packaged for single-patient use. Discard the remaining opened material after each wound closure procedure.

Do not sterilize the adhesive.

Do not place the adhesive in a procedure pack/tray that will be sterilized before use. Exposure of the adhesive to excessive heat (as in autoclaves or ethylene oxide sterilization) or radiation (such as gamma or electron beam) will increase its viscosity and may render the product unusable.