Hopson Chemical Industry

Hopson Chemical Industry

Silicone Sealant, also known as “glass glue” or “structural adhesive” is made of polydimethylsiloxane and silica, It is similar to ointment, Once exposed to moisture in the air, it will solidify into a tough rubber-like solid material.

As a leading silicone sealant supplier, Hopson® offers a comprehensive range of products, including acid silicone sealant, neutral silicone sealant, and custom OEM solutions. Acid silicone sealant is primarily used for general bonding between glass and various building materials. However, neutral silicone sealant addresses the limitations of acid silicone sealants, which can corrode metal surfaces and react with alkaline materials. As a result, neutral silicone sealant has a broader range of applications and is typically priced slightly higher than its acid silicone sealant.

Waterproof silicone sealant has excellent performance, can maintain good sealing in humid environments, prevents moisture penetration, has strong adhesion, and good weather resistance, and can adapt to different temperature and humidity changes. It is a sealing expert in humid environments.

It is widely used in waterproof sealing in humid environments such as bathrooms, kitchens, and balconies, as well as the joints between bathtubs and walls, sink edges, etc. It can also be used in large-scale projects such as building exterior walls and roofs, playing an important waterproof role to prevent rainwater penetration.

HSI-001 Waterproof Silicone Sealant

| Packing | 75g/card, 12cards/box 12boxes/ctn |

| SPEC. | White/Antibacterial For Bathroom/Kitchen |

| G.W. | 15KGS |

| CTN | 39.5*39*44cm |

Surfaces must be clean, dry, and free of dirt, grease, oil, or water.

1. Puncture tube with cap.

2. Apply the product to the substrate.

3.Replace the cap after use and store it in a cool, dry place.

Note

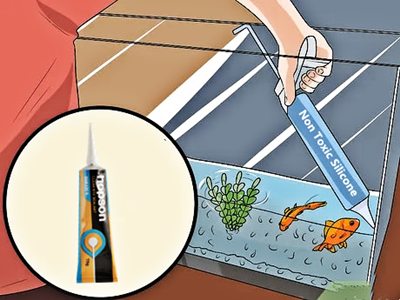

Clear silicone sealant, with its transparent finish, is mainly used in situations where transparency needs to be maintained, such as bonding glass products, sealing aquariums, etc.

For some decorative projects with high requirements for appearance, transparent silicone glue can achieve a seamless connection without affecting the overall appearance.

HSI-002 Clear Silicone Sealant

| Packing | 75g/card, 12cards/box 12boxes/ctn |

| SPEC. | Clear/Antibacterial For Fishbowl/Car Lamp |

| G.W. | 15KGS |

| CTN | 39.5*39*44cm |

Clear silicone sealant is a great aquarium-safe sealant, it is flexible can withstand constant water immersion, and is resistant to seawater and salt mist, making it perfect for fish tank repairs.

Use clear silicone sealant to fix a leaking aquarium steps

Black silicone is one of the well-known types of silicone sealant. It has an exceptional performance and it protects the surfaces from stains, moisture, and damage. Black silicone has a very low reflectivity and high absorption of light. This black RTV silicone sealant is suitable for sealing black or dark materials, such as black metal frames, dark glass curtain walls, etc. In some industrial fields, black silicone glue is often used for sealing and fixing mechanical equipment.

HSI-003 Black Silicone Sealant

| Packing | 85g/card, 12cards/box 12boxes/ctn |

| SPEC. | Black/High Temperature Resistant For Motorcycle/Car Cylinder |

| G.W. | 16.5KGS |

| CTN | 39.5*39*44cm |

Black Silicone Adhesive Sealant is a low odor, general purpose, black RTV indoor/outdoor sealant that seals, bonds, repairs, mends, and secures glass, metal, plastics, vinyl, weather stripping, and vinyl tops.

GREAT FOR

USE ON

High-Temp silicone sealant is a one-part, non-slumping temperature resistant silicone adhesive sealant designed for sealing and bonding applications with continuous exposure to temperature ranges of -85˚F to 500˚F and intermittent exposure up to 600˚F.

HSI-004 High-Temp Silicone Sealant

| Packing | 300ml/pcs, 24pcs/ctn |

| SPEC. | White/Clear/Black For Construction |

| G.W. | 8.3KGS |

| CTN | 20*25*30cm |

How to seal a bath with a large gap

Work your way around the tub. After the sealant has been applied to each seam smooth the bead with a caulk finishing tool or dip your fingertip in water and run it along with the silicone bead.

Again, do this smoothly, applying even pressure, so that the sealant is further into the seam. The water prevents the sealant from sticking to your finger, allowing you to get a lovely, smooth finish.

Silicone Sealant Colors

Silicone sealants come in various colors, each with distinct applications. Clear silicone sealant is perfect for sealing glass fish tanks, bonding car lights or interiors, and repairing aquarium utensils. White silicone sealant, often referred to as bathroom silicone sealant, is ideal for mildew-resistant sealing and bonding in sanitary facilities. Black silicone sealant, also known as structural adhesive, is used for creating anti-leak pads in gearboxes, compressors, and pumps, as well as for sealing, clogging, and weatherproofing buildings.

Moreover, as a structural adhesive, it provides robust sealing, clogging, and weatherproofing for buildings, ensuring their structural integrity and protection from the elements. Each color of silicone sealant brings unique benefits and solutions to a wide array of sealing and bonding challenges.

Silicone Sealant VS Silicone Caulk

Silicone sealant and silicone caulk are both called structural adhesives, but they serve different purposes and have distinct characteristics.

1. Uses

Silicone Sealant:

– Used where high sealing performance and durability are crucial, such as in building facades to seal glass to frames, withstanding high wind pressure and weather conditions.

– In industrial settings, it seals machinery and pipe joints to prevent gas or liquid leaks, requiring high sealing performance.

Silicone Caulk:

– Used for filling smaller gaps and cracks, such as between door/window frames and walls, or bathroom tile joints.

– Mainly for decoration and general sealing, with lower sealing strength requirements.

2. Performance Characteristics

Silicone Sealant:

– Excellent adhesion to various materials like metal, glass, and plastic.

– Good elasticity, handling temperature changes and material expansion/contraction, maintaining seal over time.

– Strong weather resistance, withstanding UV rays, rain, and chemicals, long-lasting.

Silicone Caulk:

– Weaker adhesion but sufficient for general gap filling.

– Less elastic and weather-resistant than sealant, suitable for indoor use.

– Easy to apply and adjust, ideal for DIY projects.

3. Appearance and Texture

Silicone Sealant:

– Fine, uniform texture, with regular shape after extrusion.

– Limited color options, commonly transparent, white, or black.

Silicone Caulk:

– Slightly rougher texture, with possible irregular patterns after extrusion.

– Wide range of colors, suitable for decorative needs.

4. Price

Silicone Sealant:

– Generally higher-priced due to high performance and wide application.

Silicone Caulk:

– More affordable, suitable for cost-sensitive small projects.